conformal coating thickness measuring instrument|conformal coating removal solvents : commercial A final method for measuring conformal coating thickness is a wet film measurement technique. This is very cost effective although a little cumbersome. The technique uses a comb with different size patterns that is . 28 de jan. de 2024 · bet365 Kundenservice: Garantiert schnelle Hilfe erhalten. bet365 ist ein populärer Wettanbieter, der durch zahlreiche Sportwetten und einen unangefochtene Live Wetten Bereich beeindruckt. Für sämtliche Fragen und Anliegen steht dir der bet365 Kundenservice bereit, mit dem wir uns in diesem Artikel genauer beschäftigen.

{plog:ftitle_list}

web2 de jan. de 2020 · Betiton™ UK is a top online casino for British players looking for a platform to play with peace of mind, knowing they’re getting a fair, genuine online casino experience. Besides offering a secure platform, Betiton is one of the best casinos for slots, table games, live casino games, and even sports betting.. Our online casino has a lot to .

Methods for Measuring Conformal Coating Thickness. For conformal coatings to function effectively, the key lies in achieving the right coating thickness. Printed circuit boards . Important things to consider before measuring the conformal coating dry thickness. Follow these steps to get an easy and accurate way to measure the conforma. A final method for measuring conformal coating thickness is a wet film measurement technique. This is very cost effective although a little cumbersome. The technique uses a comb with different size patterns that is .Dry Conformal Coating Thickness. Measure the dry thickness of conformal coatings to verify against IPC-A-610 requirements Wet Conformal Coating Thickness. Measure the wet thickness of conformal coatings to provide .

Ultrasonic Testing: Ultrasonic thickness gauges use sound waves to measure the thickness of the coating. The device emits ultrasonic pulses, and the time taken for the waves to bounce back from the substrate-coating interface is used to calculate the thickness. X-ray Fluorescence (XRF): XRF can be used to measure the thickness of conformal .Coating thickness Conformal coating thickness measurement methods The measurement of the conformal coating thickness on a printed circuit board (PCB) to ensure internal and international standards are met is now a critical factor in conformal coating process control.There are several methods for measurement of conformal coating thickness and .Therefore, it was concluded that CCM can be used as a powerful alternative to standard methods for measuring conformal coating thickness. Conclusions This research provides insight into the capabilities of chromatic confocal microscopy as a powerful alternative to traditional thickness measurement instruments. Micrometer, eddy current, wet film . The application of the conformal coating in a uniform and consistent coverage is a key challenge that defines the reliability of the finished product.A thin .

Dry Conformal Coating Thickness Measurement An alternative method to wet film measurement is using an eddy current system like the Positector 6000. This system is extremely quick and accurate to ±1 um. Placing the test head on the surface of the conformalCoating Thickness Instruments Overview. PosiTector 200 - Coating Thickness Measurement on Rough Surfaces. . A PosiTector 6000 probe is generally recommended over a PosiTector 200 probe for measuring coating thickness on metal substrates because – . Measurement of Conformal Coating on Printed Circuit Boards. Conformal coating (CC) is widely used to protect printed circuit board from corrosion, mold growth, and electrical failures. To ensure effective protection, the thickness of the CC layer needs to be well controlled. However, to date, the coating thickness is usually measured in a destructive way under microscopes. In this paper, we proposed to use optical . Chase Global Operations Center and Corporate Headquarters . 375 University Avenue Westwood, MA 02090 Tel. 781.332.0700 Fax 781.332.0701

Current practice for measurement of the thickness of conformal coating typically involves measurement with a mechanical gauge with a least count of 25µm (0.001 inches) or 12.5µm (0.0005 inches). . There are many available techniques for measuring coating thickness, but most were found to have significant limitations that made them . People then take averages to estimate the coating thickness. These are just two of the many avenues to take. The goal is to find at least one measurement technique that helps a company maintain tight PCB quality control. The correct PCB coating thickness matters. Failing to use enough conformal coating could result in the component not getting .

Dry Conformal Coating Thickness Measurement An alternative method to wet film measurement is using an eddy current system like the Positector 6000. This system is extremely quick and accurate to ±1 um. Placing the test head on the surface of the conformal Conformal Coating Thickness Measurement Methods The measurement of the conformal coating thickness on a printed circuit board (PCB) to ensure internal and international standards are met is now a critical factor in . Industry expert Bob Willis explains how to use "sticky dots" to measure conformal coating thickness.It is the economical choice that retains the uncompromising quality of DeFelsko coating thickness and inspection instruments. Conforms to ISO 2178/2360/2808, ISO 19840, ASTM B244/B499/D7091/E376, BS3900-C5, .

AN001 Au/Pd coatings in the nm range on printed circuit boards 0.48 MB AN007 Thickness measurement of conformal coatings on printed circuit boards 0.99 MB AN034 Measuring the copper thickness in plated through-holes on PCBs 0.57 . Hardness measuring instrument for determining properties such as indentation hardness and the depth-dependent . The galvanize coating is applied by the sheet metal supplier either by hot-dip galvanizing or by electrogalvanizing. If the zinc coating thickness were uniform, the thickness of the subsequently applied paint coating could be measured using a conventional magnetic induction coating thickness measurement instrument.Conformal coatings are usually applied as very thin coatings, providing the maximum protection possible using the thinnest amount of material. This minimizes heat entrapment, additional weight addition, and a variety of other concerns. Normal thickness with most conformal coatings is anywhere between 1 to 5 mils (25 to 127 microns) with some coatings applied at an even .

Typically, conformal coating is applied between 1 to 5 mils (25 to 127 microns). There are three main ways to measure the thickness of a conformal coating: Wet film thickness gauge-Wet film thickness can be measured directly by using gauges that have a series of notches and teeth - each tooth having a calibrated length. The gauge is placed .Fig. 1 a) Confocal measuring setup, b) interferometric coating thickness measuring principle (zoom) Fig. 2 a) Frequency modulation of the intensity signal. b) Corresponding thickness peak in the Fourier spectrum. a b . Conformal coating thickness inspec-tion in the production process The combination of the camera basedThe Positector 6000 N0 S1 is a precision instrument designed for the measurement of conformal coating thickness. With a coating range thickness of 0–25 mils (0–625 µm), it offers versatility across various coating applications.

Fig.1: A 6000-NS1 measures on an acrylic coated printed circuit board with a solid copper ground plane . Solution #2 : For PCBs without copper ground planes. Our ultrasonic PT-200 B/Std gage measures conformal coating thickness on some printed circuit boards without a copper ground plane. Ultrasonic measurement has limited application on PCBs because the probe cannot be .Ultrasonic Testing: Ultrasonic thickness gauges use sound waves to measure the thickness of the coating. The device emits ultrasonic pulses, and the time taken for the waves to bounce back from the substrate-coating interface is used to calculate the thickness. X-ray Fluorescence (XRF): XRF can be used to measure the thickness of conformal .An IBM circuit board from a NASA Space Shuttle computer with a conformal coating applied. Conformal coating is a protective, breathable coating of thin polymeric film applied to printed circuit boards (PCBs). Conformal coatings are typically applied with 25–250 μm [1] thickness on electronic circuitry to protect against moisture and other substances. .

Portable Digital Refractometers vendor

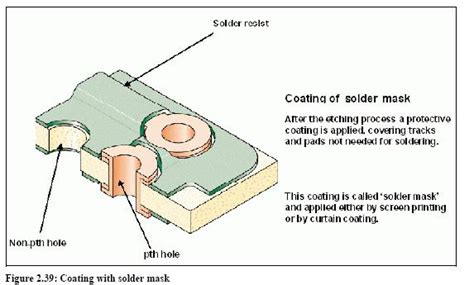

solder mask vs conformal coating

how to inspect conformal coating

how to apply conformal coating

webOpzoeken van adressen, plaatsen, routes vergelijken om uw reisweg overal in België te plannen.

conformal coating thickness measuring instrument|conformal coating removal solvents